Recent Posts From Features

Marketing shouldn’t always sell

There’s been a recent push (most likely by the bean counters) to...

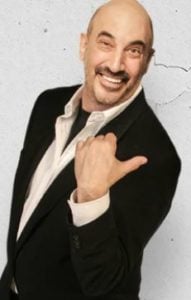

What is the Reality of Selling? The way you do the things you do

Jeffrey, what’s the easiest way to make a sale?Jeffrey, what’s the best...

Is your dealership embracing technology?

I recently attended MODEX 2024, and this year’s show was highly...

Future Business Silos

You have been following your standard business silos for many, many years....

- Nuts & Bolts

- Podcasts

- Products

- Shifting Gears

H&E Equipment Services reports first quarter 2024

H&E Equipment Services, Inc. announced results for the first quarter...

Queen City Robotics Alliance Spring and Summer Events

Summer is almost here… The volunteers and teams at Queen City Robotics...

Mazzella wins award contributing with #GLAD2024

Mazzella Companies has been presented with an award for its contribution to...

Piab USA announced a new location in Canton, MA

Piab USA has announced the relocation of its headquarters to a new,...

Columbia Machine Palletizer Division joins Techmatik at Warsaw Pack in Poland

A team from the Columbia Machine Inc. Palletizer Division joins Techmatik...

PTDA hosts Industry Immersion Conference

The Power Transmission Distributors Association (PTDA) held the first...

Nucor Warehouse Systems hosts Open House in Houston

Nucor Warehouse Systems (NWS) has opened its doors to its Texas location at...

Terex reports strong First Quarter 2024 results; raises full-year outlook

Sales of $1.3 billion increased 5% year-over-year Income from operations of...

Episode 482: Warehouse fire suppression systems with Telgian

Welcome to another fiery episode of The New Warehouse Podcast! Today,...

Episode 481: Achieving a fully autonomous supply chain with Nimble Robotics

In this episode of The New Warehouse Podcast, Jonathan Briggs, VP of Sales...

Episode 480: The future of safety in warehousing with Powerfleet

The latest episode of The New Warehouse Podcast, featuring Scott Walker,...

Episode 479: Insights into the 3PL Industry with Aaron Hodes

In this episode of the New Warehouse podcast, we’re thrilled to welcome...

Episode 478: Exploring cold chain logistics with the team from Cold Chain 3PL

The New Warehouse Podcast shines a spotlight on a crucial sector of cold...

Episode 477: 3PL insights with Bulu CEO, Paul Jarrett

In this episode, we dive into a conversation that reshapes how we think...

Episode 476: Fabric’s bold approach to micro fulfillment solutions

This episode of The New Warehouse Podcast transports us into the heart of...

Episode 475: The Pivotal Role of Barcodes in Supply Chain Management with GS1

Barcodes are often underrated and underappreciated, but they play a pivotal...

Kassow Robots launches the world’s first 7-axis cobot series with a controller integrated into the base

Greater flexibility for mobile solutions & additional space savings for...

NPE: The Plastic’s Show 2024 debuts never-before-seen show features

The Plastics Industry Association (PLASTICS)has announced brand-new...

COVAL launches the new generation of Multi-stage Mini Vacuum Pumps: The CMS M Series

The mini pump with max performance! The CMS M series, the latest addition to...

Toyota’s 80V Electric Pneumatic Forklift earns 2023 GOOD DESIGN Award

Toyota Material Handling receives the 2023 GOOD DESIGN Award as a testament...

NORD offers optimum conveyor functionality with NORDAC ON/ON+ VFDs

NORDAC ON/ON+ variable frequency drives deliver intelligent control of...

Revolutionizing industrial torque reaction solutions with carbon fiber

GCI Engineered Solutions is thrilled to unveil the groundbreaking carbon...

LEDtronics expands industrial controls with non-relampable panel indicator series

Continuing to expand its offerings of LED indicators for industrial,...

CLARK has announced the launch of the SE25-35 lithium-ion forklift

CLARK Material Handling Company has announced the launch of the SE25-35, a...

Cromer Material Handling earns Diamond Award from Bobcat Company

Bobcat Company recognized Cromer Material Handling as a top-performing...

Cimcorp has announced new VP of Operations

Leveraging three decades of expertise in managing international projects,...

Robroy Industries® appoints Alex Erwin as Business Development Manager

Robroy Industries® Enclosures Division has announced the appointment of...

Conveyco Technologies welcomes Brian Keiger as VP of Sales

Conveyco Technologies has announced the appointment of Brian Keiger as Vice...

Pettibone Celebrates 75th anniversary of Cary-Lift

Pettibone Traverse/Lift, LLC is celebrating the 75th anniversary of the...

Cavaion Baumann USA welcomes Paul Bilson as Director of Dealer Development and National Accounts.

Paul will lead the effort to strengthen the Baumann dealer network...

Invent Analytics wins RetailTech breakthrough award

The winning AI-driven Returns Positioning solution streamlines and...

Brent Barcey joins OSARO as SVP to fuel growth in e-commerce

Barcey’s broad experience in selling advanced robotics, logistics and...